Motorcycle Modifications

rule #1 - keep it factory, keep it simple

This is my rule #1, at least - no modifications should prevent the bike from being returned to its original condition.

The basics of this rule are that the primary factory harness is not to be altered, the chassis is not to be cut/drilled, and the modifications' outward appearance should appear as close to the original as possible. Like I said, this is my rule, and it is your bike. I just have a lot of mechanical sympathy for my bikes and cars, so I avoid butchering them at all costs.

In Australia, the modifications required for my motorcycles are an ADR exemption ADR 57 sections referencing the locations of specific controls.

plan & prepare

With the modifications I typically make, I need to understand the motorcycle’s electrical system, cable routing, and switchgear harnesses. So, the first step is to obtain a good/correct factory workshop manual and find a good online parts catalogue site for the bike.

I’ll also source factory replacements for any parts I might need to modify—switchgear assemblies, levers, etc.- and keep these new parts aside should I need to return the bike to its original condition.

Maintaining the factory wiring harness requires sourcing the correct electrical connections, terminals and wire colours. This can take some research, and acquiring the right tools for any connectors you need is essential. Learn to read wiring diagrams and understand the functions of the individual control circuits before you start.

Each motorcycle will be different, often similar, but you need to prepare for the differences, especially if you’re in a hurry to ride the bike like I usually am.

switches - switchgear

Switchgear housing type - are the bike’s throttle cables mounted to the switchgear housing, or, are the throttle cables run through to their own housing?

I dont like to mess with the factory throttle cables. It can be a pain to get alternate cables to fit/function, and it just opens up an opportunity for something to go wrong while I’m riding the bike. Keep the factory throttle cables.

With the SWM I found an affordable eBay switchgear set that looked factory in appearance and accepted the factory throttle cables.

The Royal Enfield used a genuine Royal Enfield throttle housing from a different market (non-Australian market) that included a headlight switch. I repurposed this switch as an indicator switch and got to retain the factory throttle cables.

The two TRXs have their throttle cables to a separate housing, so there is no issue here.

The Z900, in Australia, has throttle cables running to a switchgear housing. However, the Z900SE uses a separate housing for the throttle cables, so I used those parts for my bike.

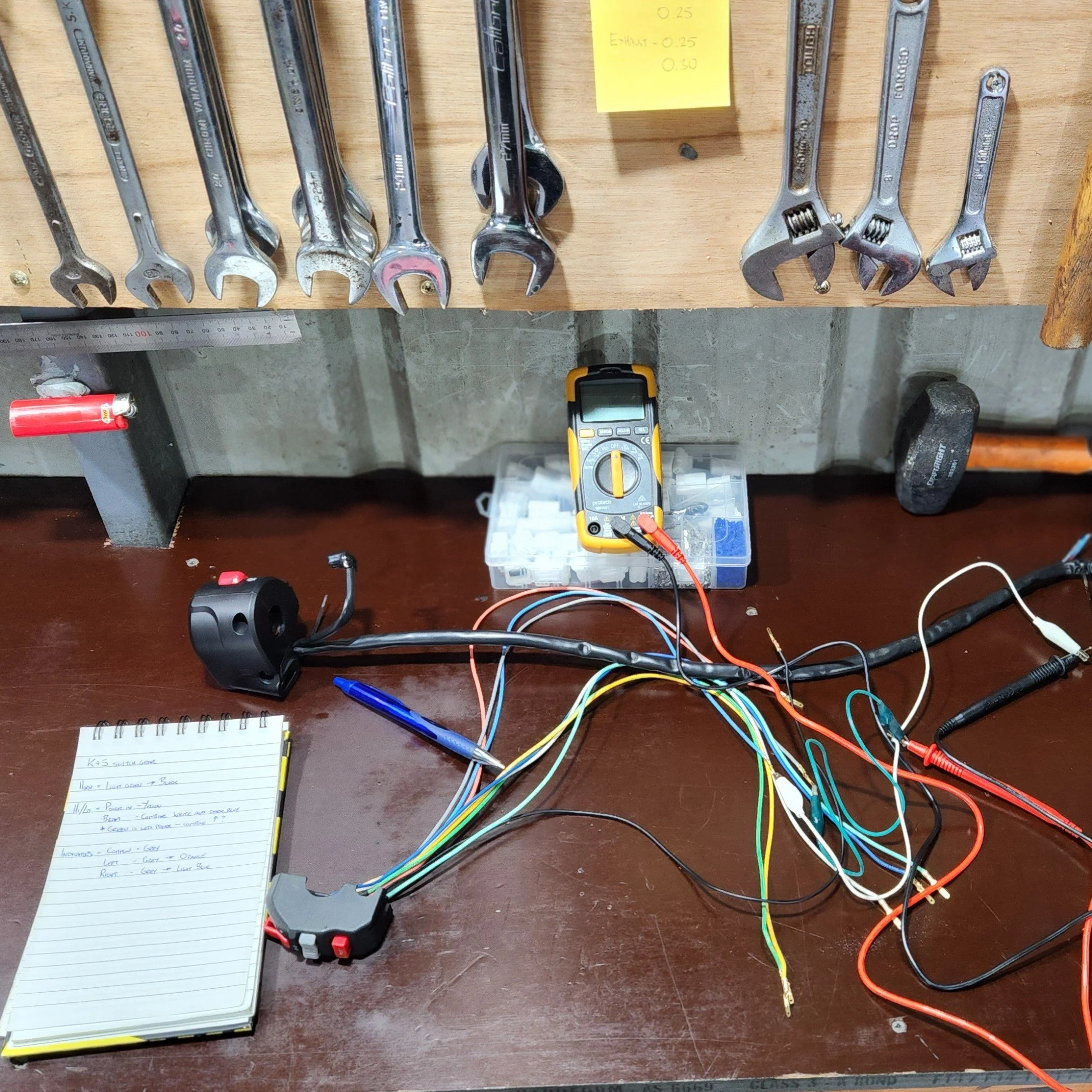

switches and testing

With my arrangement of switches, I often have to add at least two—I typically set these up as “starter” and “kill switch.” I like to have these two switches mounted so they’re easy to reach with my thumb, and I’ve done this a few different ways.

For the SWM I mounted a KTM copy switch assembly under the switchgear housing using a 3D printed adapter plate.

I 3D-printed a housing to mount two generic switches to the factory switchgear for the Royal Enfield. One switch is a latching, normally open switch, and the other is a momentary switch.

The two TRXs required a completely custom housing, and I used a combination of latching and momentary switches.

The Z900 uses a K&S switchgear with a custom backing plate, which incorporates the two switches.

handlebar real estate

Moving the clutch lever to the right-hand side handlebar and making room can be problematic. The TRXs caught me here, hence the custom-designed switchgear housing. I’m yet to revisit this design, but I did have longer handlebars made to replace the factory ones, which allows for more options in locating clutch levers and switchgear.

Bikes that use a switchgear block with throttle cables aren’t so much of a problem. You can usually get a clutch lever between the front brake lever mount and the switchgear housing.

clutches

When I started this project, I got the usual feedback - “get an automatic gearbox/clutch”. That’s not how I like to ride bikes for a start, but more importantly, I didn’t want the need for a special clutch/gearbox to limit my choice in future motorcycles.

If you’re into auto clutches, I say go for it; I recommend EFM as a starting point. I’ve never used one of their clutches, but I know somebody (another LAE amputee) who has, and he swears by them. I’ve contacted EFM personally to discuss my options, and the guys there are 10/10 to talk with—really good people who know their stuff.

I run with the bike's standard clutch and either a rerouted clutch cable or a second clutch cable, depending on my options for clutch switch mounting. Clutch switches are essential; if the bike has one, you must find a way to keep it. I’ve done this two different ways. The first is to use a generic rear brake light switch fixed to the bike's frame and linked to the clutch lever arm at the engine. The other option is to retain the factory clutch lever, clutch switch and clutch cable and run a second clutch cable from your new right-hand side clutch lever to the clutch lever arm at the engine - you have a “clutch” cable and a “switch” cable. This later option is the easiest way to do things. You will need a way to fix your “switch” cable to the lever arm at the engine. In my case, I 3D printed a small clip.

Clutch levers. I have a box of clutch levers and lever mounts from all the experimenting/testing I’ve done. But if you need a short lever, I recommend Righteous Stunt Metal levers. The TRX I required a short lever to clear the fairing, while the SWM, Royal Enfield, and the Z900 all got away with generic (full-length) clutch lever arrangements - typically XR200/250 or DR400 type levers. My Royal Enfield used the SWM’s original lever, so sometimes you don’t have to look far for the right one. Do a lot of testing before committing to ensure correct clutch engagement/disengagement and get the right feel for your riding style.

Front brake light switches

If you’re doing things like me, you will now have a bike with a brake lever and clutch lever on the right-hand side handlebar - with the brake lever positioned above the clutch lever. I find this more natural and safer to ride with.

Doing this, however, often introduces an issue with the front brake light switch fouling with the relocated clutch lever. Typically, the front brake light switch needs to be removed/replaced/relocated.

I’ve used hydraulically operated brake light switches without issue on non-ABS bikes. I’m not going to claim to be an expert on braking systems, but I don’t like the idea of interfering with the braking circuit of any ABS system, so on my ABS bikes I do whatever it takes to retain a switch similar to the factory part. For my Royal Enfield and Z900, I made my own brake light switches. This way, I avoid corrupting a perfectly functional braking system…. because stopping safely is important to me.